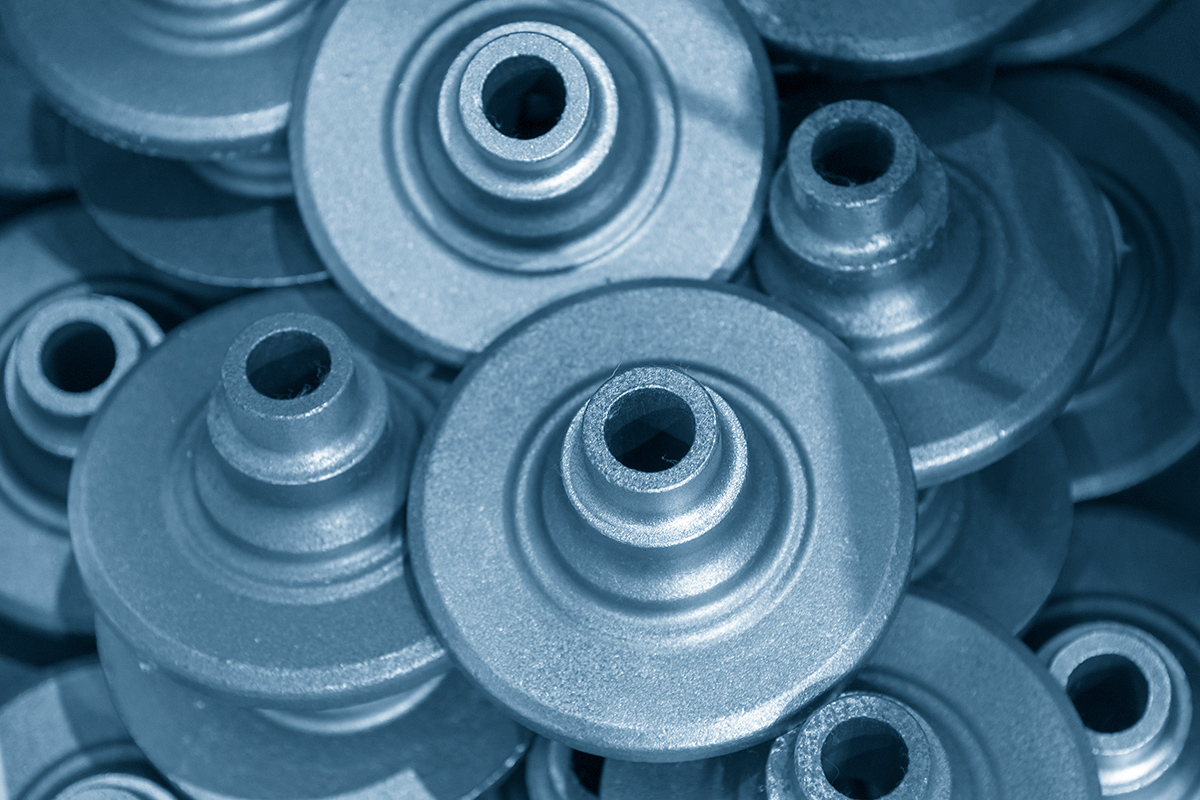

Completed casted products

Through casting, it is possible to produce complicted parts. This is an advantage in the manufacturing as no further assemblies are required. We are experts in managing the casting process, starting from engineering the needed casting molds to materials and methods. By finding the best production combinations for our customers, we can find the most effective way to deliver products.

Casting materials according your choice

The castings can be categorized according to the materials used in the process:

– Ferrous metals (cast iron and cast steel)

– Copper metals (Bronze and Brass)

– Aluminiums

– Zinc and magnesium

There are several standards related to casting materials. Some of these standards are universal, some national and there are also manufacturer´s own standards. In many cases, final product requirements are giving the guidelines by which the standards need to follow. Xpoint and their supplier network can help you to find most cost effective way to produce your products.

Best casting method for every part

According to your request regarding the casting method, amount of parts or requested material, Xpoint will find the most suitable solution for you. We can offer holistic packages, including design and manufacturing of casting molds and models. Also, we can recommed the best casting method based on the customers material needs and lot size. Examples of typical casting methods:

Sand casting, hand and machine molding

– Weight of product varying from 50 grams up to several tons

– Batch sizes vary from individual castings to several hundreds

– Most common materials: Steel, cast iron and bronze

We will look after:

- Manufacturing the molds and sample products

- Machining of cast parts

- Surface treatments (zinc-coating, powder coating and painting)

- Adding extra parts (like bearing assemblies and grease nipples, etc.) and completing assemblies

- Warehouse services

- Packaging and delivery according to customer requests

Precision casting

– Weight of product varying from 10 grams up to few kilos

– Batch sizes vary from one to several

– Most common materials: Light alloys, zinc, mangnesium, etc.

We will look after:

- Manufacturing the molds and sample products

- Machining of cast parts

- Surface treatments (zinc-coating, powder coating and painting)

- Adding extra parts (like bearing assemblies and grease nipples, etc.) and completing assemblies

- Warehouse services

- Packaging and delivery according to customer requests

Permanent mold casting, chilled casting and pressurized die casting

– Weight of product can vary from 10 grams up to few kilos (pressurized mold casting) or up to tens of kilos (chilled cast)

– Batch sizes vary from hundreds (chilled casting) up to several thousands (pressure mold casting)

– Most common materials: Aluminium, Brass, zinc, magnesium, etc.

We will look after:

- Manufacturing the molds and sample products

- Machining of cast parts

- Surface treatments (zinc-coating, powder coating and painting)

- Adding extra parts (like bearing assemblies and grease nipples, etc.) and completing assemblies

- Warehouse services

- Packaging and delivery according to customer requests

Choosing between Casting or other processes?

Xpoint is capable of delivering castings as a final product, including machining and surface treatment chosen by customer. This will ensure that our customers´s will have parts ready to be assembled without delays. Your product quality is guaranteed.